- Home

- Knowledge

- PCB

- PCB

- Why does long stored PCB need to be baked before assembly or running through reflow oven?

Why does long stored PCB need to be baked before assembly or running through reflow oven?

- The purpose of baking is to remove the moisture from the PCB.

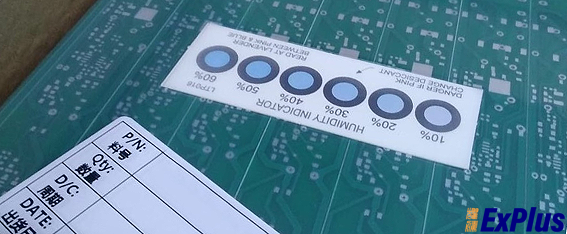

- No matter the PCB is at production site or still in vacuumed package, both would increase the risk that PCB can absorb moisture.

- If PCB is stored at a bad storage condition or over storage period, these would also make the PCB absorb moisture easily.

- The high temperature would cause inner board moisture evaporation when assembly the damp PCB.

- The PCB will have blister or delamination due to steaming.

Maybe you would like to read more:

- What is the role of holes on printed circuit boards (PCB)? What are PTH / NPTH holes? And what’s the difference between two of them?

- Why do we not recommend using the PCB which exceeds the shelf life?

- How is the Number of PCB Layers Counted? What is the Difference between Double Sided PCB and Multi-layer PCB?

- Why are PCBs designed stack-up?